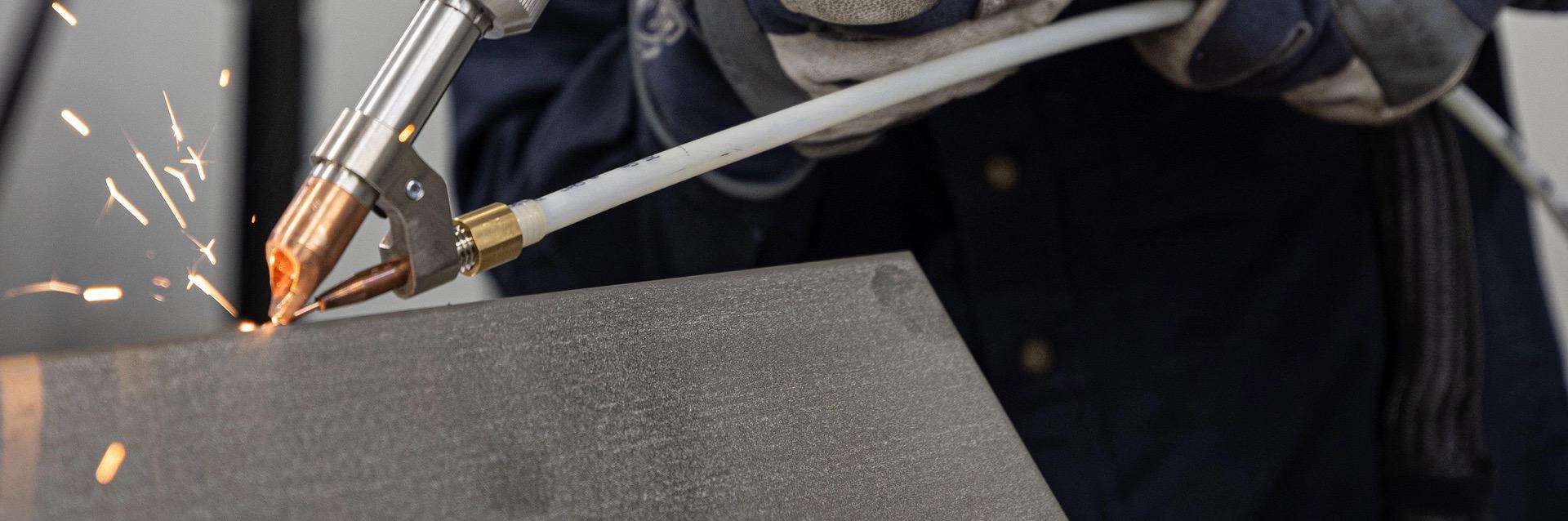

Training

Lightspeed Welding is here to partner with you at every step of your handheld laser welding journey. We have partnered with The Handheld Laser Institute to offer everything from basic on-site operator training to advanced application engineering and procedure qualifications. Whatever your organization might require to accelerate the ROI of handheld laser welding, we can tailor a unique services package to suit your needs. Whether you're interested in basic on-site operator training, advanced application engineering, or development of WPS's & PQR's for your common materials/joints, we're here to help.

Our Mission

Educate and empower individuals, businesses, and entire indesutries by providing the knowledge and resources required to accelerate the industrial adoption of handheld laser welding.

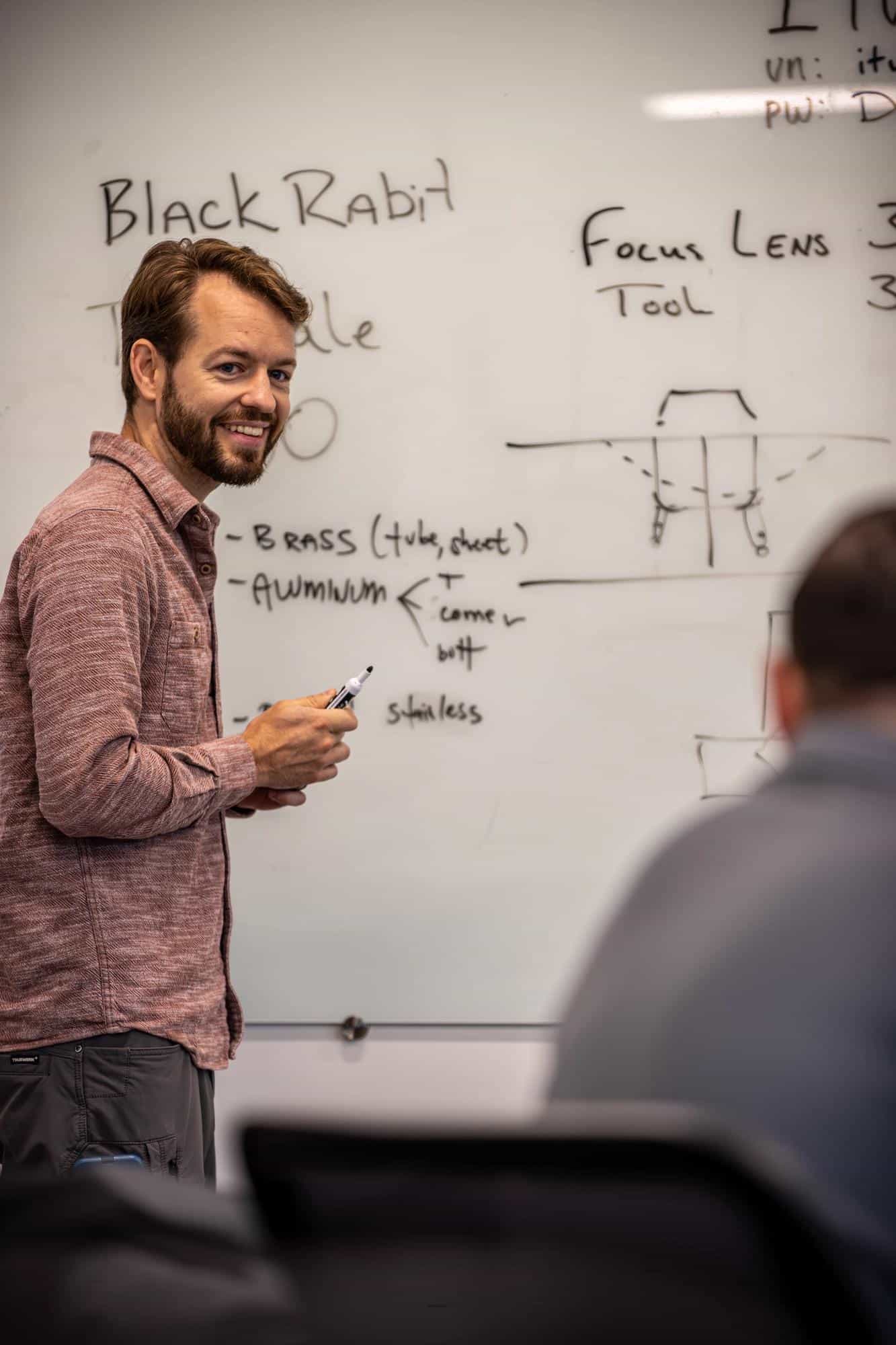

About Us

The Handheld Laser Institute was founded by Rex Alexandre in early 2024 and is focused on accelerating the industrial adoption of handheld laser welding by providing education, training, and cutting-edge research based on real-world welding applications. Engineering and educational services can be provided at our world class lab in the greater Seattle area, or directly at customer’s facilities across North America.

Services

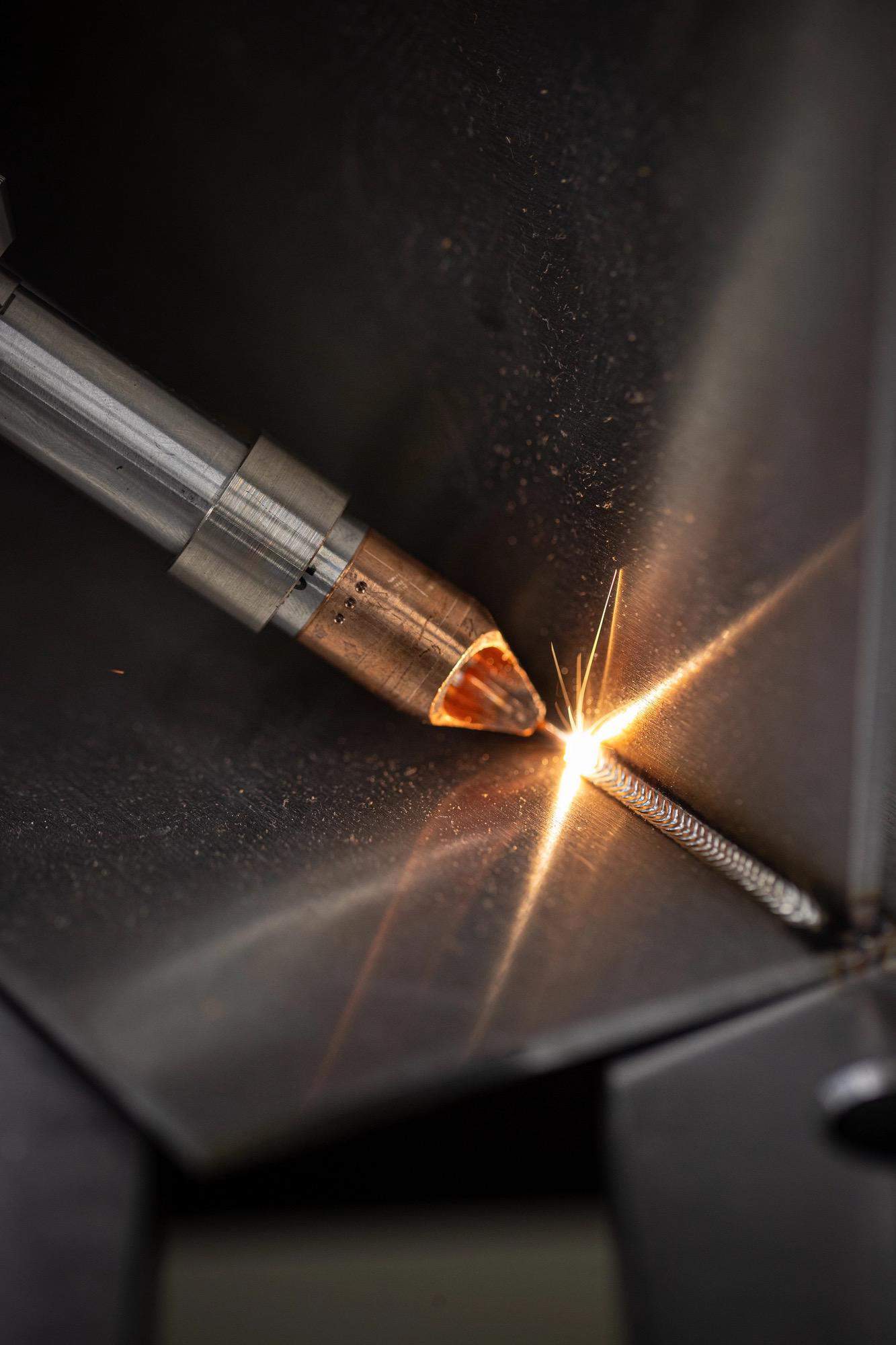

Procedure Qualifications

- HHLI will develop and qualify welding procedures for your application

- All qualifications testing performed at a third-party testing facility

- WPS and PQR documents will be provided to your code requirements

Consulting

- Weld strength & metallurgical analysis of GMAW/GTAW vs. HHLBW

- Materials & weldability testing

- Mechanical performance & weld design allowables

- Manufacturing guidelines & best practices

- Process monitoring, reliability, and inspection

- Hardware development & improvements

Applications Development

- Demo parts to your specifications

- Customer supplies raw material

- Low quantity manufacturing runs upon request

On-site Training

- 1-2 days basic training consisting of 20% classroom and 80% hands-on instruction

- Includes applications & process development on your parts

Contact